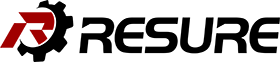

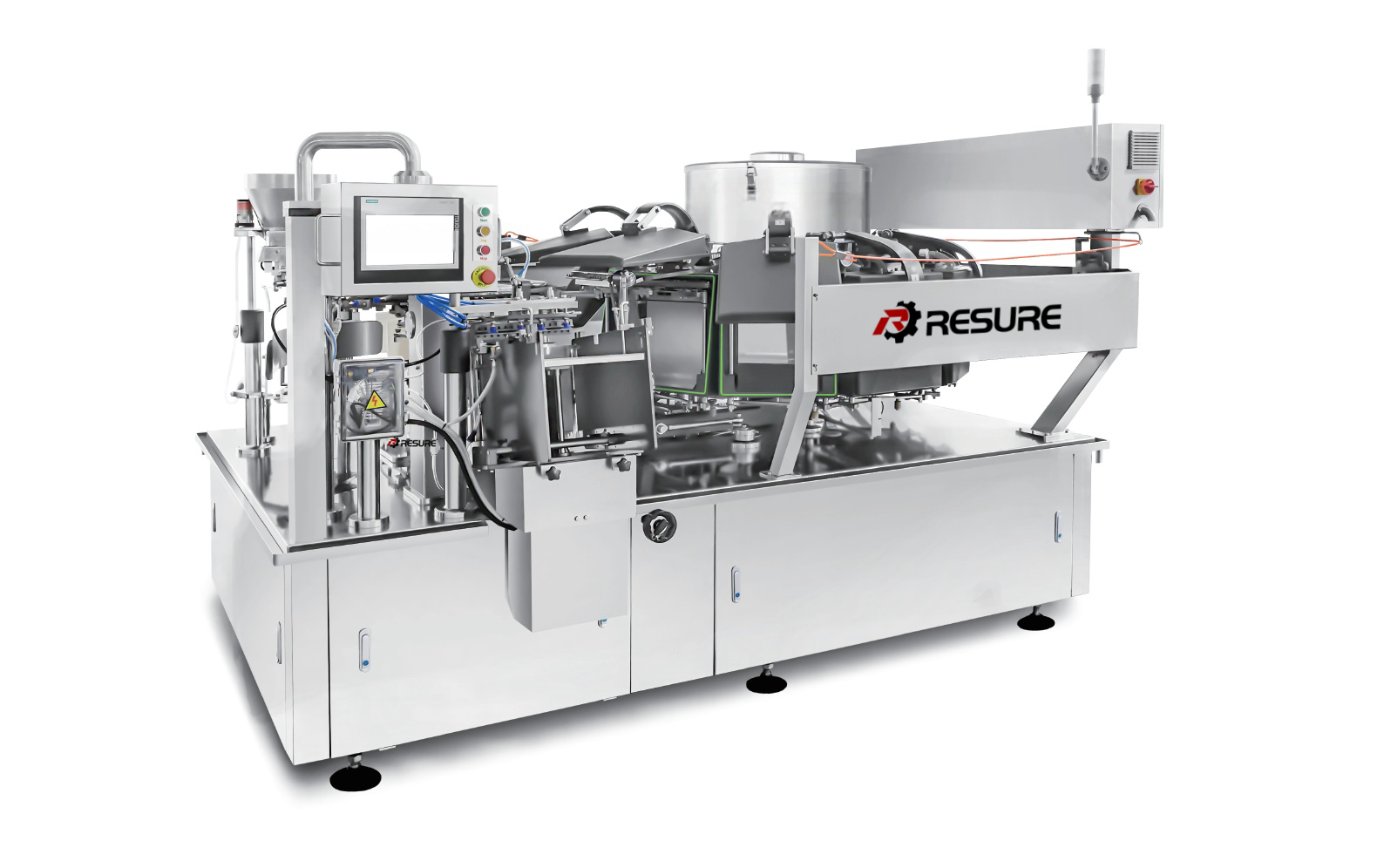

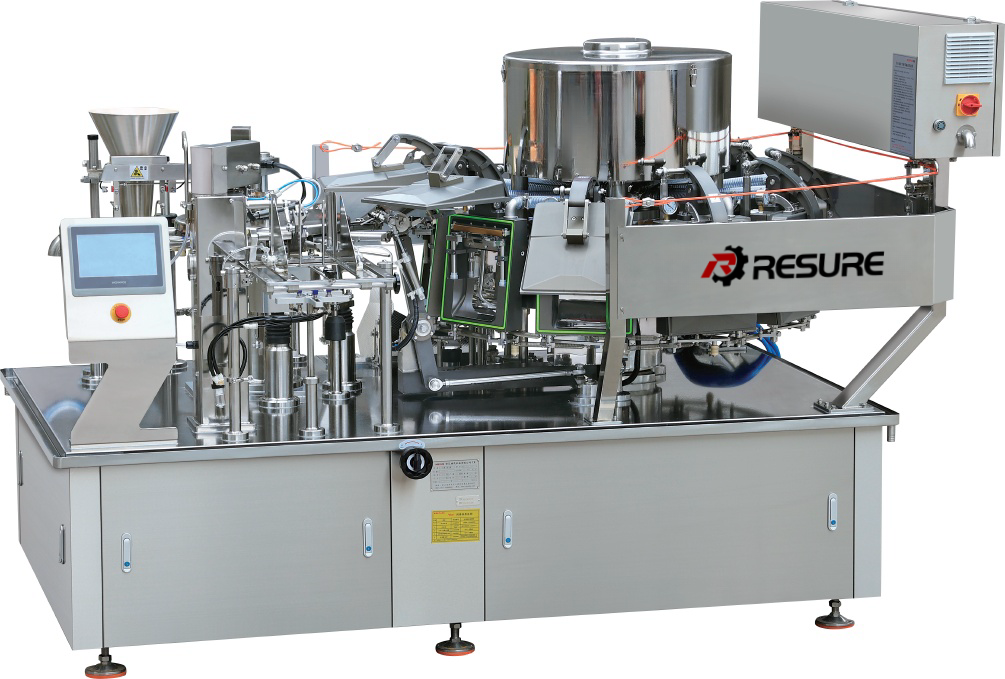

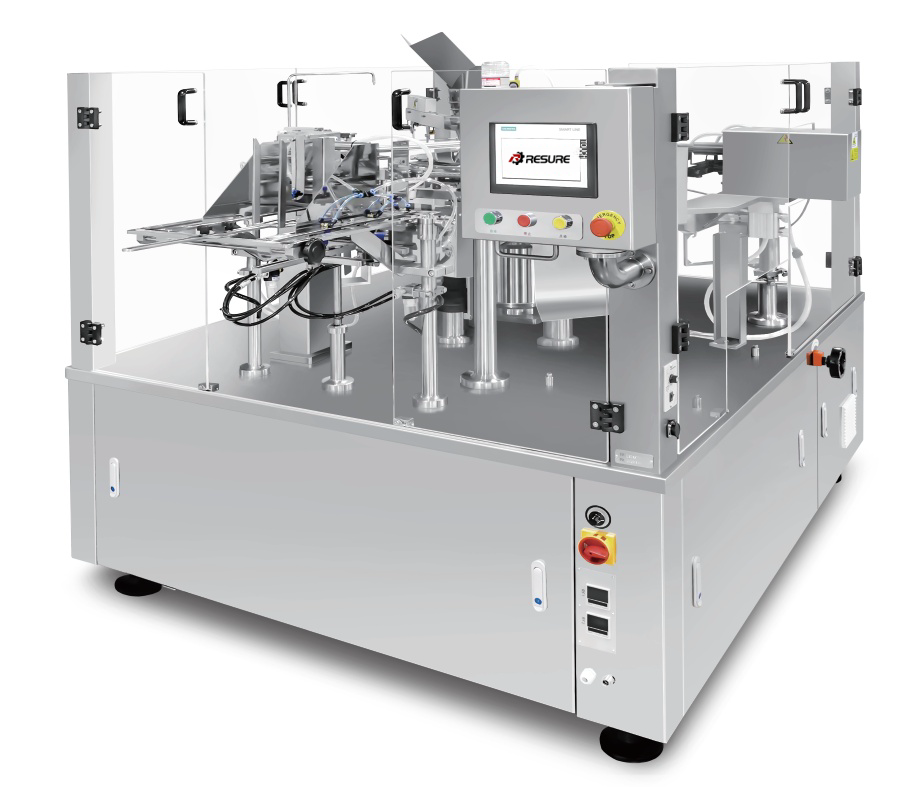

RST-CL Thermoformed Plastic Cups Sealing Machine

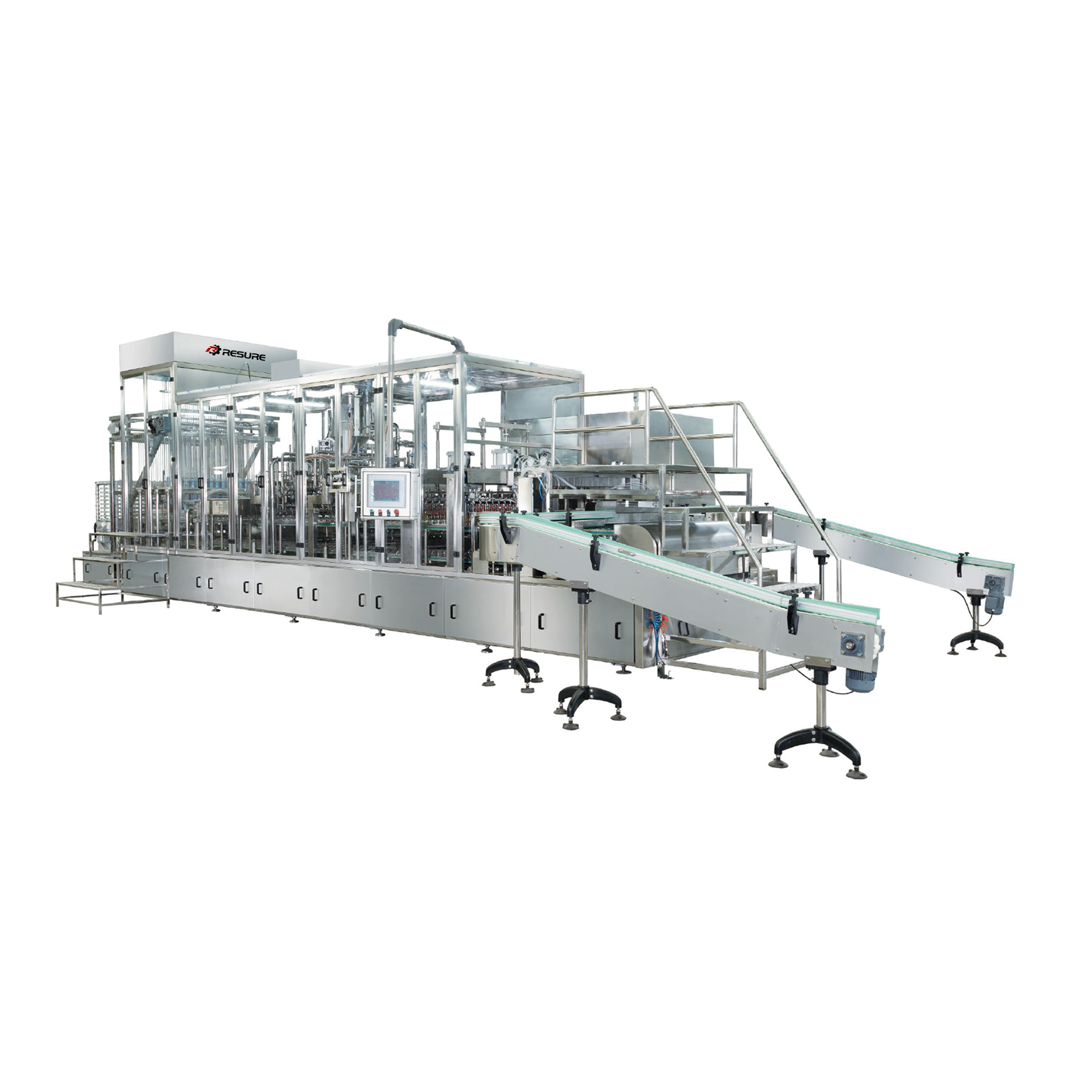

This highly efficient machine integrates thermoforming, wrap-around labeling, precise filling, sealing, date printing, and cutting into one system. It primarily produces cup-packaged foods such as yogurt, cream, and butter. Automated operations complete the entire process, from film to finished cups, offering high efficiency, energy savings, and flexibility.

Packaging Effect

Products Categories

Get A Free Quote

Data Sheet

| Model | RST-CL4 | RST-CL6 | RST-CL8 | RST-CL12 | RST-CL24 | RST-CL32 |

| Volume(mL) | 50~150 | 50~150 | 50~150 | 50~150 | 50~150 | 50~150 |

| Capacity (Cups/h) | 4500~5000 | 6000~7500 | 8000~10000 | 15000~18000 | 30000~40000 | 40000~48000 |

| Total Power (kW) | 8 | 10 | 14 | 50 | 75 | 90 |

| Air Consumption(m³/min) | 1.2 | 1.5 | 1.8 | 1.0 | 1.5 | 2.0 |

| Air Pressure (MPa) | 0.65~0.75 | 0.65~0.75 | 0.65~0.75 | 0.65~0.75 | 0.65~0.75 | 0.65~0.75 |

Technology

- Integrates plastic cup forming, wrap-around labeling, filling, sealing, date printing, punching, and finished product conveying into a single system, with full process automation. This effectively improves production efficiency and reduces labor costs.

- The machine uses a Siemens PLC and touchscreen control system from Germany, ensuring easy operation and stable performance. Temperature control is precise and reliable, and it is equipped with a Banner photoelectric sensor from the USA, SEW servo reduction motors from Germany, and FESTO pneumatic components from Germany. All key components are sourced from internationally renowned brands, ensuring long-term stable operation of the equipment.

- Equipped with a dynamic quantitative fruit particle mixing system, achieving precise and consistent ingredient dosing, ensuring each cup of product is uniform and meets the requirements of different formulations.

- Equipped with a laminar flow air purification system, effectively reducing airborne contaminants during production and ensuring food safety.

- It can be connected to a CIP (Clean-in-Place) cleaning system, enabling automatic cleaning and complying with hygiene standards in the food industry.