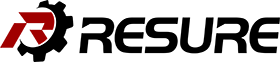

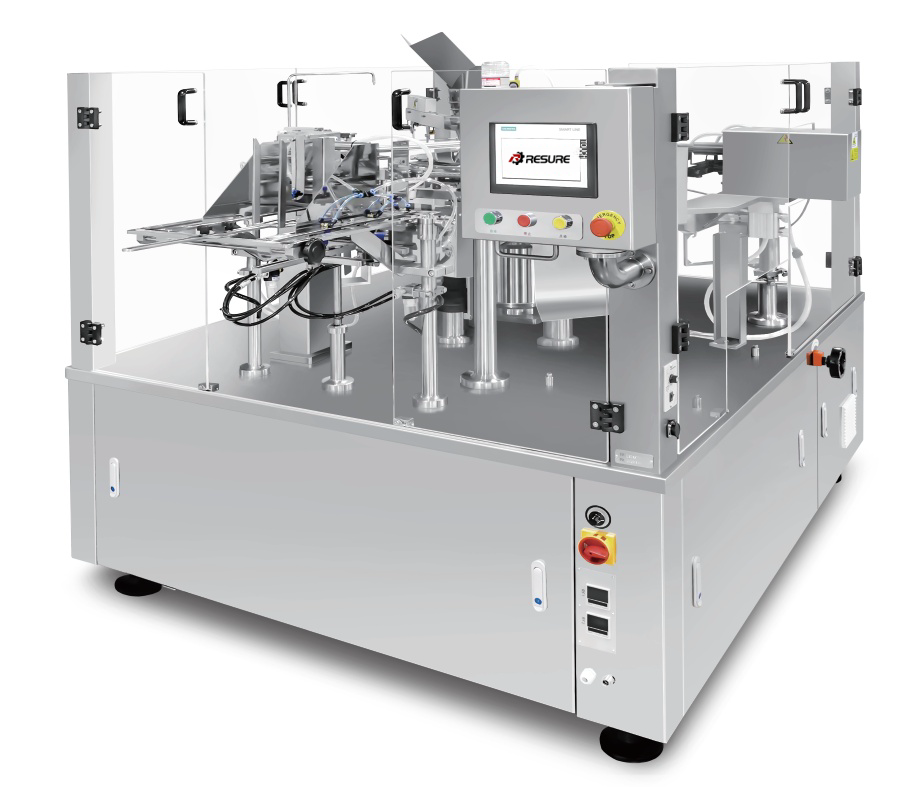

RS-RC1800 Rotary Pre-formed Cups Sealing Machine

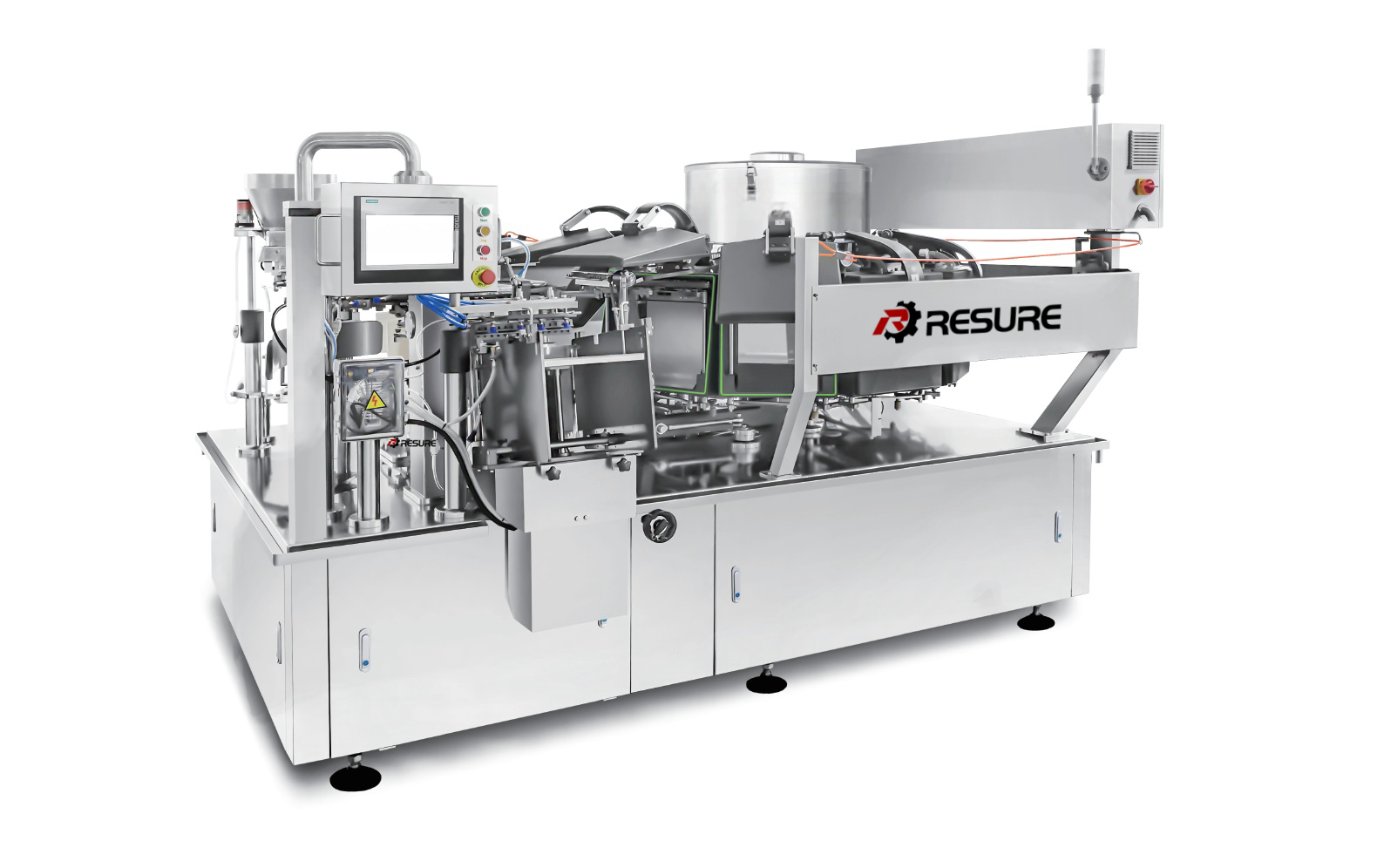

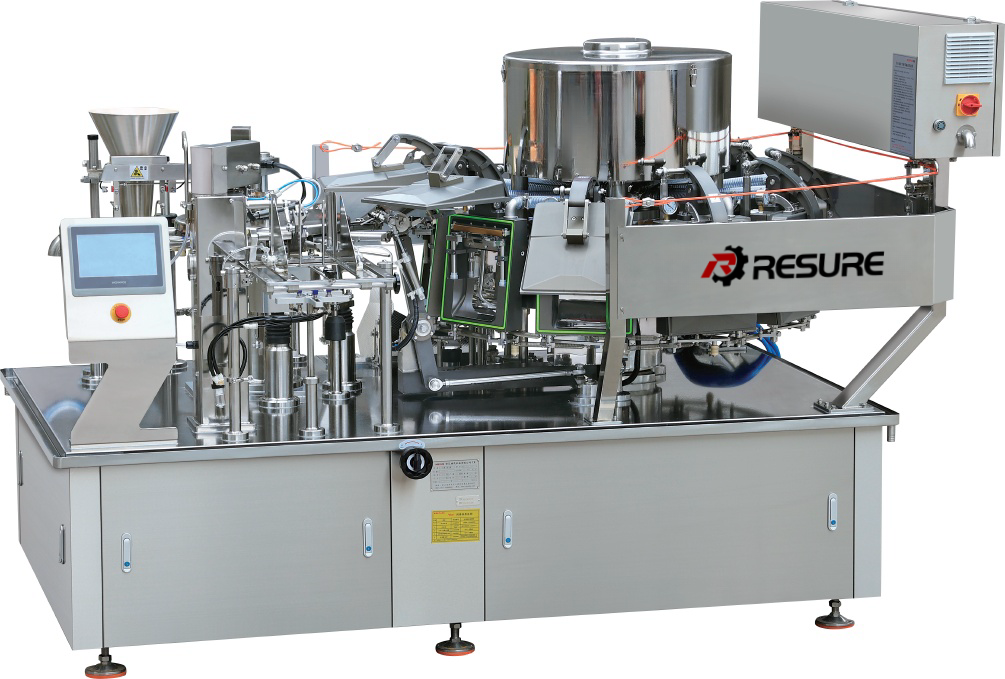

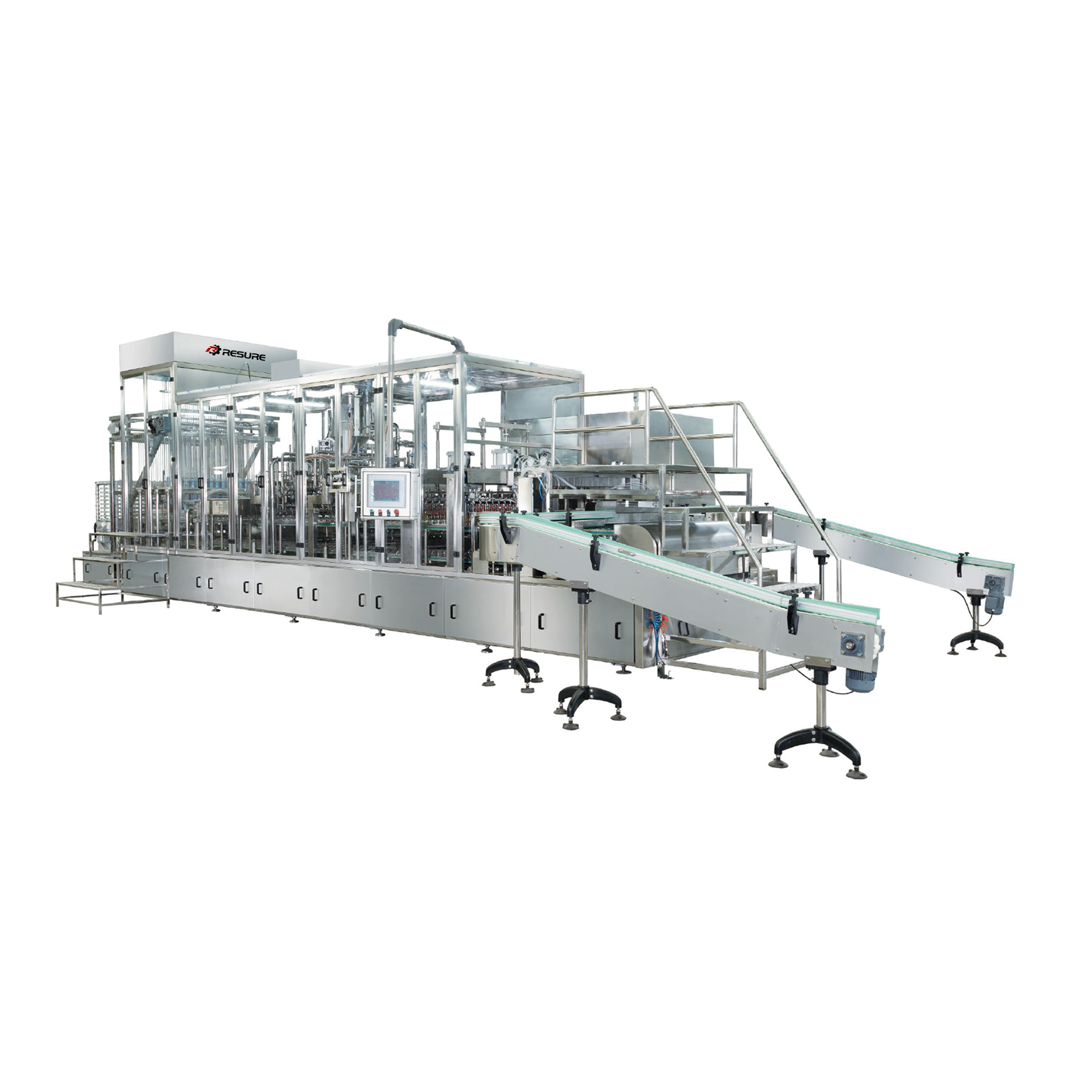

This is a highly efficient, fully automated packaging system for sealing plastic, paper, aluminum-plastic, and other cup-type products. The equipment integrates automatic cup feeding, precise filling, roll film sealing, and cup discharging into one seamless process, utilizing a rotary design to ensure smooth coordination of each step.

Packaging Effect

| Model | RS-RC1800 |

| Capacity (Cups/h) | 1600~1800 |

| Total Power (kW) | 2.2 |

| Air Consumption(m³/min) | 0.45 |

| Air Pressure (MPa) | 0.5~0.75 |

| Dimensions (mm) | 1500×1000×1750 |

| Weight (kg) | 450 |

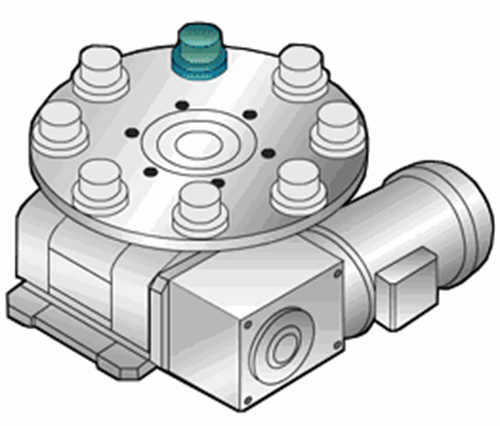

Transmission and Template Traction System

Utilizes a sub-line intermittent transmission system composed of a drive motor, reducer, and smooth transmission device. The system precisely guides the cups through a traction transmission chain, positioning device, and aluminum template. A stainless steel plate beneath the aluminum template supports the cups, ensuring stable operation.

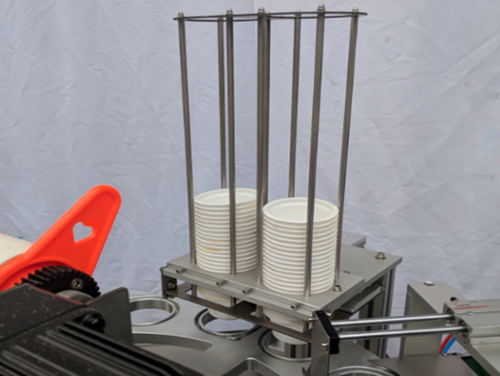

Automatic Cup Dropping Device

A pneumatic device drives this device and includes pneumatic components, a cup storage rack, and a positioning and cup separation unit. It enables precise automatic cup dropping, eliminating manual intervention and ensuring efficient and stable production.

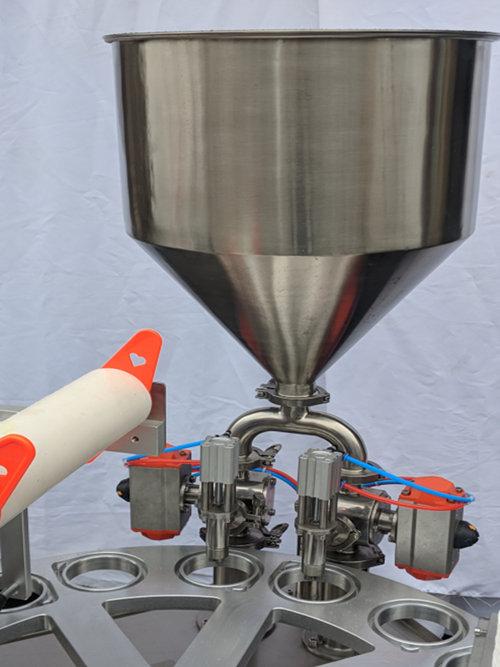

Automatic Filling Device

Adopts a piston-type quantitative filling system with an adjustable filling volume ranging from 50 to 500ml.

Sealing System

Includes heating, constant temperature control components, temperature sensors, and a sealing device, equipped with a heat-sealing plate and sealing head to ensure optimal sealing for each cup. An optional ribbon coding system is available for printing production dates and batch numbers, facilitating traceability.

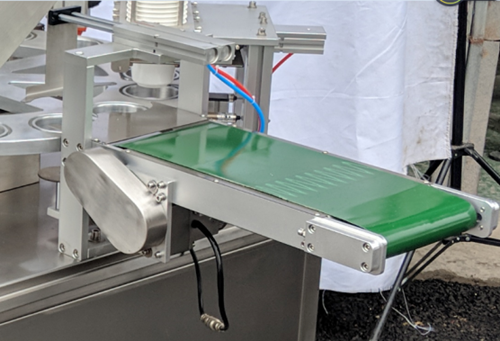

Automatic Cup Discharge Device

Equipped with an automatic ejection system that smoothly pushes out sealed cups and transfers them to the next processing stage.