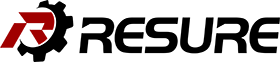

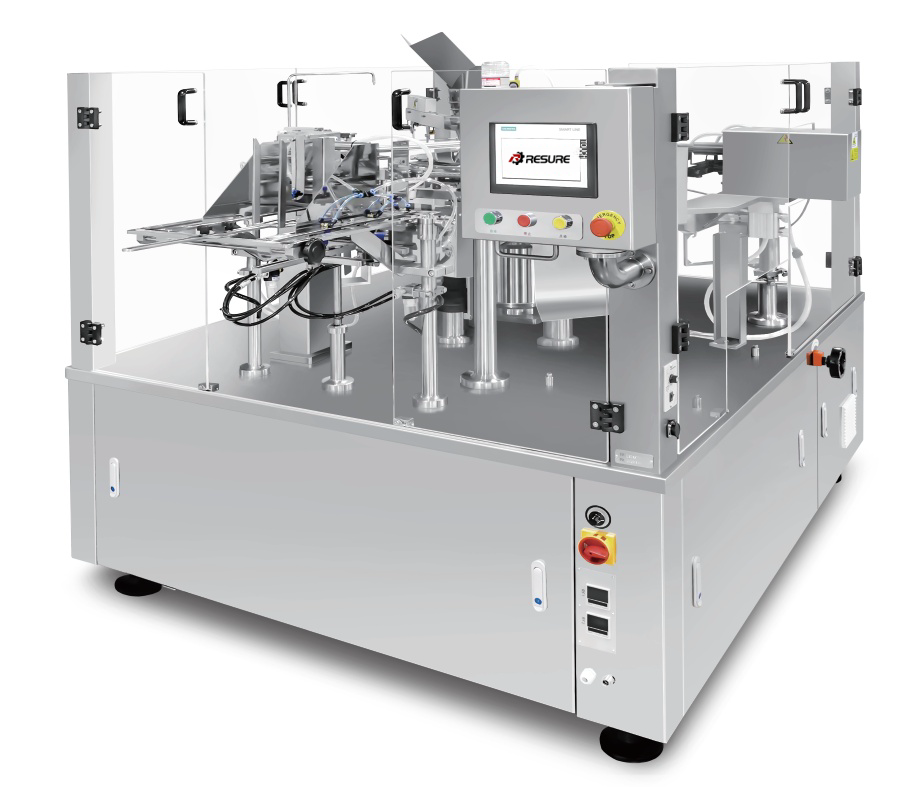

RS-B600 Vertical Flow Packaging Machine

Specifically designed for small sauce packages, with a compact structure, small footprint, fast packaging speed, and precise measurement.

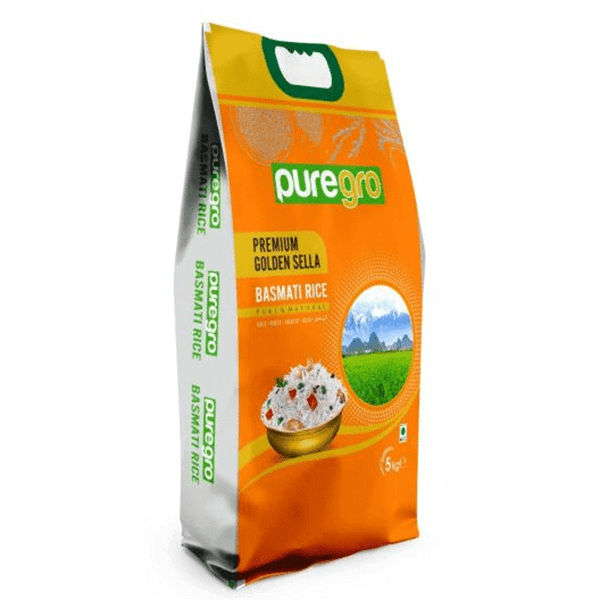

Packaging Effect

RSB-600 Doypack Filling Machine Data Sheet

| Model | RSB-600 |

| Pouch Length (mm) | 380~600 |

| Pouch Width (mm) | 250~500 |

| Packing Speed (bpm) | 0~10 |

| Sealing Type | Straight-line seal,mesh seal(tooth pitch 1mm) |

| Sealing Width(mm) | 5-20(Customized) |

| Total Power (kW) | 2 |

| Air Pressure (MPa) | 0.65 |

| Dimensions (mm) | 1677×1140×1450 |

RSB-600 Doypack Filling Machine Video

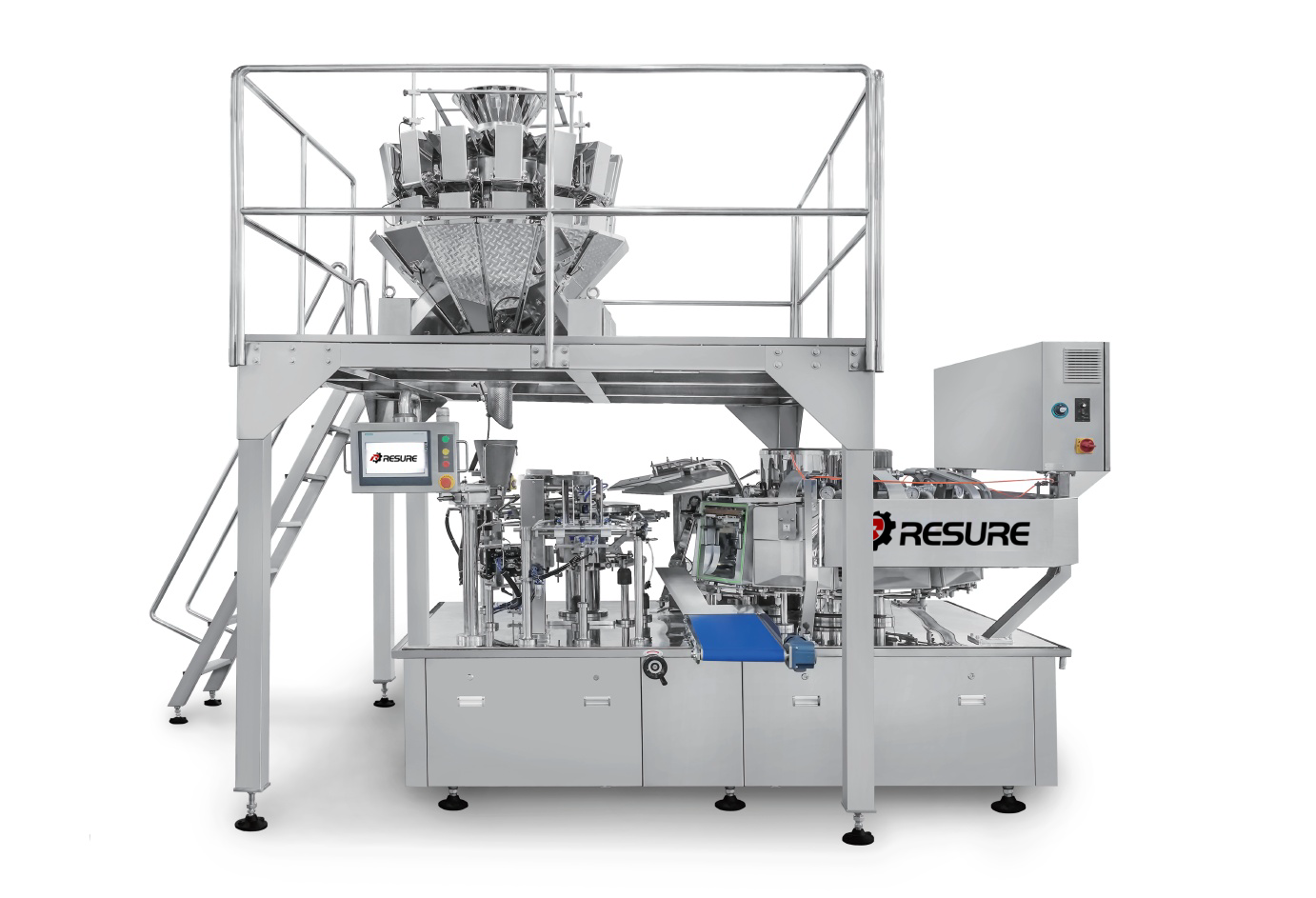

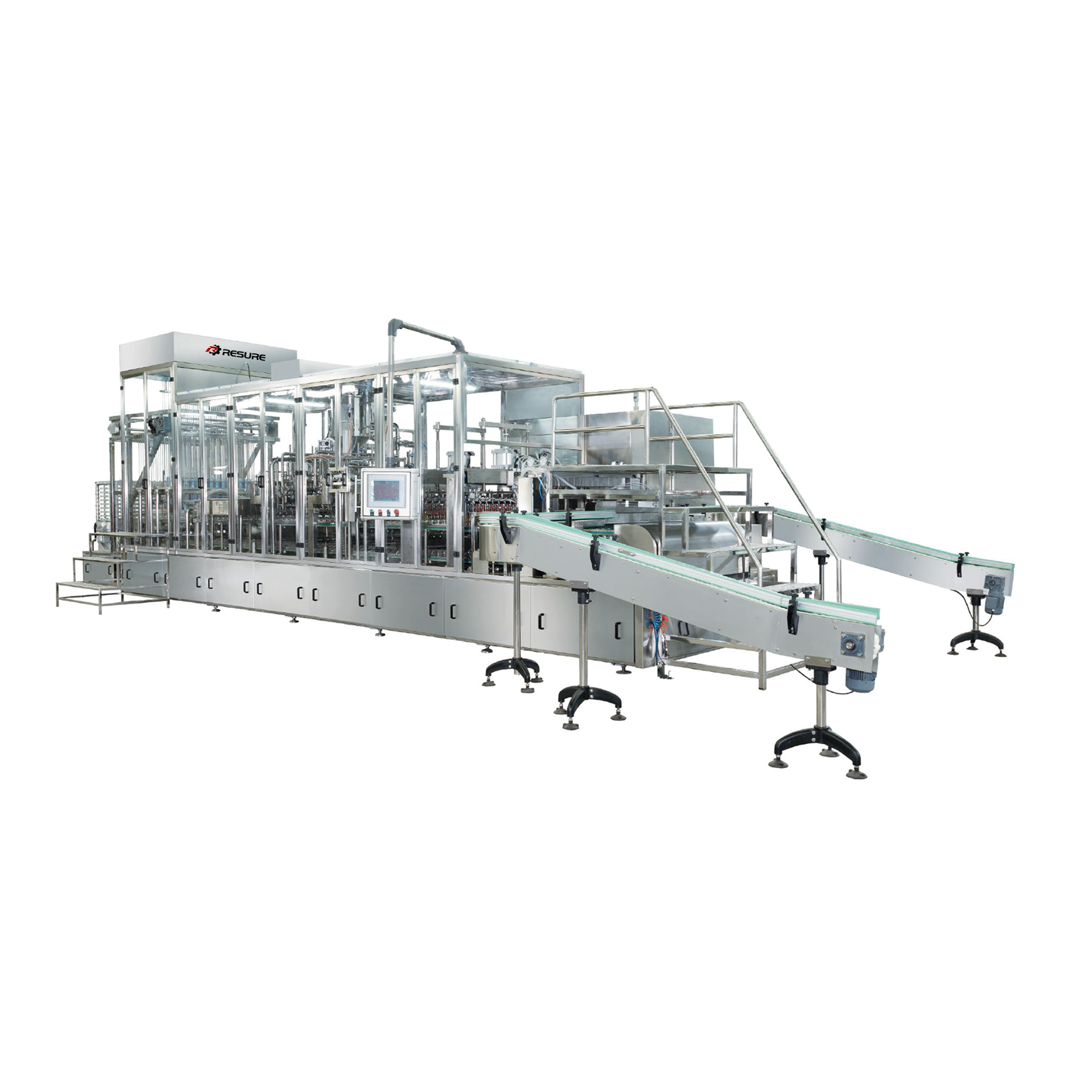

Vibrating Storage Hopper

Made of 304 stainless steel to ensure safety and hygiene, preventing contamination of the packaged product. The hopper is equipped with a vibration function to effectively enhance the discharge speed and ensure a smooth, clog-free material flow. Additionally, it features an intelligent detection sensor that monitors the material level in real time and automatically stops discharge when the material is insufficient.

Automatic Feeder

The Z-type automatic feeder adopts a stable and efficient conveying structure to ensure smooth material transportation to the designated position. It is equipped with a visual window for real-time monitoring of the feeding process.

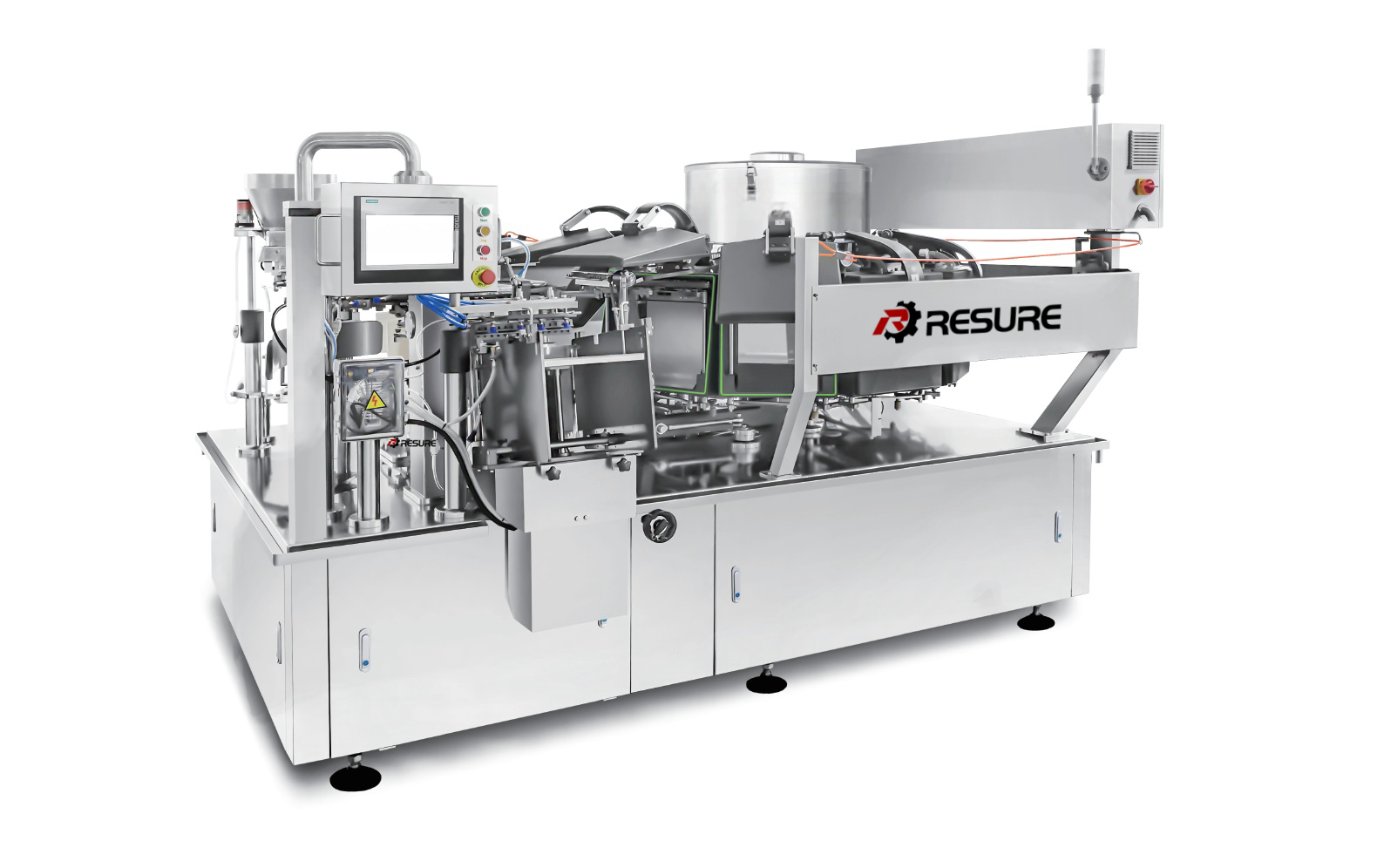

Electronic Weigher

Equipped with a 14-head weigher and 5L hoppers, ensuring high-precision and high-efficiency weighing. It is suitable for various weight ranges, including 1 kg, 5 kg, and 10 kg, meeting diverse packaging requirements.

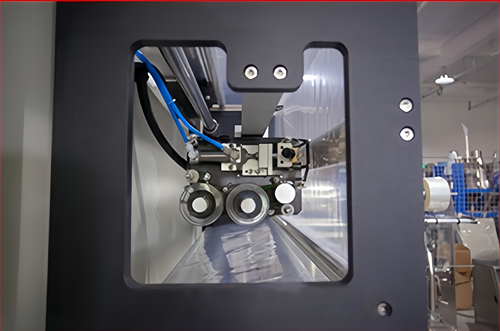

Ribbon Coding Machine

Capable of printing production dates and batch numbers on bags with clear and precise print quality.

Electronic Components

The machine is equipped with a PLC control system for precise management of overall operation, ensuring smooth performance without jamming or system crashes, thereby enhancing production reliability and efficiency.

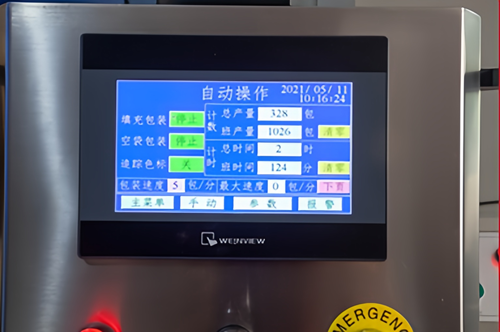

Electronic Touchscreen

Supports multiple language settings and allows one-touch adjustments without the need to stop the machine for parameter configuration.

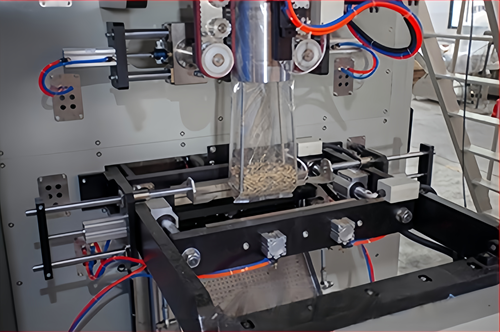

Gusseting Device

The gusseting device is controlled by a cylinder to form gusseted bags, ensuring a neat and well-structured bag shape. It can be customized for different gusset designs based on production requirements, enhancing the visual appeal and market competitiveness of the packaged product.