Integrated Absorbent Pad Pouch-Making & Packaging System: An Efficient Solution for Poultry Products

I.Background and Objectives

1.1 Client Overview and Requirements Summary

This project was initiated by a poultry processing company based in Eastern Europe, specializing in producing and distributing portioned chicken products. The client has a well-established processing system and stable sales channels. In response to increasing market competition and evolving consumer demands, the client seeks to reduce packaging costs, improve packaging efficiency, and optimize space utilization in cold chain logistics — all while maintaining product quality and presentation standards.

1.2 Packaging Method and Application Scope

This project utilizes an absorbent pad combined with film pouch packaging, integrated with modified atmosphere sealing technology. It is suitable for poultry products such as chicken legs, wings, and breasts, and can be extended to automated packaging of other fresh meat products. This packaging method ensures product freshness and transportation safety while enhancing shelf display appeal, making it ideal for supermarkets, chain stores, and wholesale distribution channels.

1.3 Pouch Packaging VS. Traditional Tray Packaging

Comparison Criteria | Pouch Packaging | Traditional Tray Packaging |

Material Cost | Both absorbent pads and pouch films are supplied as rolls, resulting in lower overall material costs. | Composed of prefabricated or thermoformed trays, sealing film, and sheet-shaped absorbent pads, with relatively high material costs. |

Equipment Integration | The main packaging machine can handle absorbent pads supplied in roll form, automatically performing cutting, positioning, and attachment. It integrates seamlessly with pouch forming, filling, gas flushing, and sealing processes, achieving a high level of automation and minimizing manual intervention. | Absorbent pads require pre-cutting and are typically placed manually or by a separate device; trays also need to be manually loaded or supplied with a dedicated tray loading system, resulting in a lower level of integration. |

Flexibility | Pouch size can be quickly set and adjusted within the specified range according to requirements. | Tray size changes require mold replacement, which can be time-consuming and less convenient. |

Transportation and Storage Space | Pouch packaging enhances stackability, leading to more efficient use of space during cold chain logistics and storage. | Tray packaging has a fixed volume and occupies more space, resulting in higher overall transportation and storage costs. |

1.4 Project Objectives

This project aims to deliver an automated packaging line for the client that integrates automatic feeding, weighing, automatic cutting, and application of absorbent pads, bag forming, product loading, gas flushing, and sealing, achieving the following objectives:

○ Improve packaging efficiency: achieve an automated packaging speed of 20–25 packs per minute.

○ Reduce operating costs: significantly lower material cost per pack by replacing tray packaging with bag packaging.

○ Optimize logistics: reduce packaging volume and improve utilization of transport and cold storage space.

○ Enhance product freshness and display: absorbent pads absorb blood moisture, improving shelf appearance and extending shelf life.

○ Support multi-product compatibility: adapt to various meat specifications such as chicken drumsticks, wings, and breasts, enhancing equipment versatility and adaptability.

II. Packaging Process

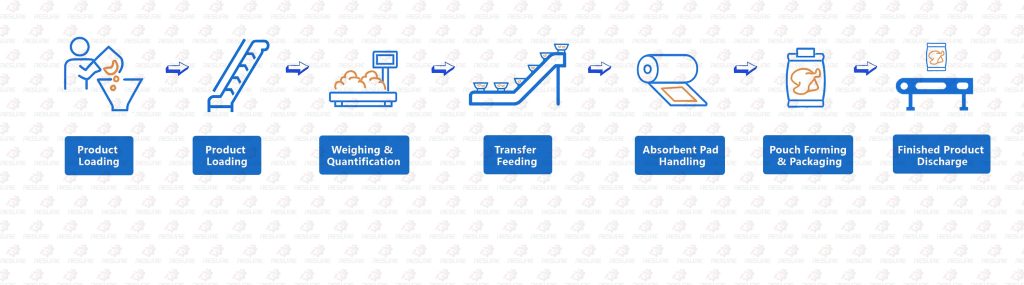

This project utilizes an automated bag packaging system, with core processes including feeding, weighing, absorbent pad handling, bag forming, packaging, and finished product discharge. The entire workflow is efficient, continuous, and highly integrated. Detailed steps are as follows:

(1) Product Loading: Operators load products such as chicken drumsticks, wings, and breasts into the initial feeding hopper.

(2) Primary Conveying: A steep-angle elevatorconveyor transports the products to the electronic weighingplatform smoothly, effectively preventing product accumulation or backsliding.

(3) Weighing and Quantification: A multi-head electronic combination scale weighs the material to ensure each package meets factory standards.

(4) Transfer Feeding: The weighed product is discharged directly into a bowl elevator via the discharge port, which lifts it to the high-level feed inlet of the packaging machine, enabling efficient connection and stable feeding synchronized with the main machine’s operation rhythm.

(5) Absorbent Pad Handling (Key Process): The packaging machine feeds absorbent pads from rolls, using an automatic tensioning and positioning system to cut the pad material automatically and precisely adhere it to a designated position on the packaging film, ensuring alignment with the bag shape and providing a stable base for subsequent bag forming.

(6) Pouch Forming and Packaging: The packaging film is thermo-sealed and formed by molds to create bags with embedded absorbent pads. The weighed product is automatically filled into the bags, and gas flushing (e.g., nitrogen or mixed preservation gases) can be applied before sealing to enhance product freshness and display quality.

(7) Finished Product Discharge: After sealing, the finished bags are conveyed via the discharge conveyor to the downstream packing area or manual collection zone, ready for cold chain distribution.

III. Technical Highlights

3.1 Automated Absorbent Pad Handling System (Key Highlight)

○ Automated Cutting of Roll Absorbent Pads: The system features high-speed, precise cutting capability, continuously cutting the absorbent pad roll according to preset specifications to ensure consistent dimensions.

○ Accurate Positioning and Adhesion: Equipped with a high-precision servo positioning system, the cut absorbent pads are accurately adhered to the designated area on the packaging film, preventing misalignment and double application, thus improving adhesion stability.

○ Consistency in Bag Formation: The film with the adhered absorbent pad is guided into the bag forming unit by a synchronized tension control system, ensuring stable bag shaping with no wrinkles or detachment of the pad, effectively guaranteeing smooth subsequent filling and sealing processes.

3.2 High-Efficiency Packaging Performance

○ Stable Operating Rhythm: The entire line operates at a steady speed of 20–25 packs per minute, maintaining high productivity without compromising packaging quality.

○ Flexible Weight Range: Supports various target weight settings (e.g., 300g, 500g, 1000g), allowing for quick switching via scale parameter adjustment to meet diverse packaging requirements.

3.3 High Scalability and Flexible Adaptation

○ Multi-Product Compatibility: Suitable not only for poultry products like chicken drumsticks, wings, and breasts, but also for fresh red meats such as beef and pork.

○ Adjustable Packaging Parameters: Film width, absorbent pad size, and pad placement position can be flexibly adjusted according to product shape, enhancing line compatibility.

○ Modular Design: The system supports optional modules for feeding, weighing, and discharge, enabling easy future expansion or product upgrades.

IV. Mine Configuration List

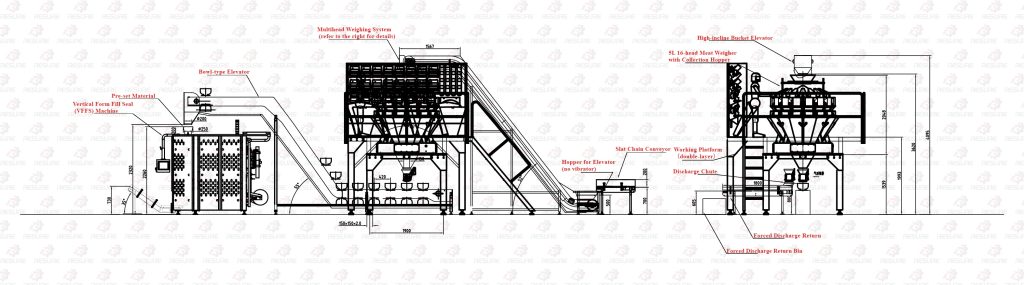

Number | Equipment | Description |

1 | Inclined Conveyor | Chain plate width: 400 mm (effective width: 300 mm); pitch: 254 mm; baffle height: 75 mm; sidewall height: 100 mm; equipped with a drip tray. |

2 | 5L 16-Head Multihead Weigher | 16-head configuration; single hopper volume: 5L; equipped with a collecting hopper; suitable for precise weighing of large pieces such as chicken drumsticks and wings. |

3 | Double-Layer Working Platform | Dimensions: 3500 × 1550 mm; split left and right sections; upper deck is detachable; includes fixed cleaning rack. |

4 | Bowl Elevator | Transfers weighed products to the packaging machine’s infeed port, ensuring seamless integration between weighing and packaging processes. |

5 | Vertical Packaging Machine | Integrates automatic absorbent pad cutting and placement, film bag forming, product filling, gas flushing, and heat sealing into a single streamlined operation. |

6 | Chain Plate Conveyor | Constructed from stainless steel, cleat height: 75 mm; sidewall height: 200 mm; designed for stable and efficient product transfer. |

V. Summary

This project is driven by the core objectives of increasing efficiency, optimizing costs, and enhancing product competitiveness. By implementing a highly integrated, all-in-one packaging system, it serves as a powerful alternative to the traditional tray-based packaging model. The system offers strong adaptability and stable operation, making it particularly well-suited for the long-term development needs of modern meat processing enterprises, especially in large-scale production, cold chain distribution, and product upgrades.