Intelligent Tray Packing Production Line for Meatballs and Meat Patties

I. Background

With the continuous development of the food industry, consumers have higher demands for the hygiene of food processing and the consistency of product packaging. This is especially true for uniquely shaped foods such as cylindrical meat patties and meatballs. Traditional manual operations are inefficient and prone to product damage or contamination.

To address these challenges, this solution is specifically designed for food enterprises, utilizing robotic arm technology for automatic picking and integrated tray loading and sealing. With a focus on efficiency, safety, and precision, it enables fully automated operations from incoming raw materials to packaging for uniquely shaped products. Introducing a vision inspection system and soft robotic grippers ensures accurate identification, damage-free handling, and precise placement of each product. This resolves issues of low efficiency and food safety risks associated with traditional methods, while significantly improving packaging quality and production efficiency.

II. Overview

This solution focuses on the automated packaging process for uniquely shaped foods such as cylindrical meat patties and meatballs. It adopts an integrated design of robotic gripping and tray sealing to achieve efficient, precise, and damage-free product handling and packaging. By combining a vision inspection system with soft robotic gripper technology, the solution ensures accurate product identification and stable handling throughout the process, further enhancing production efficiency and packaging quality.

The production line is built around a PLC control system, which coordinates the operation of all linked equipment to create a highly efficient and intelligent packaging solution.

III. Product Specifications

3.1 Product Details

● Shape: Cylindrical meat patties coated with breadcrumbs

● Weight: Base weight 113.2g; 125g after adding egg wash and breadcrumbs

● Dimensions: Diameter 40mm, Length 100mm

3.2 Performance Requirements

● Capacity: 1.5–2 tons/hour

● Speed: 120 ppm (packs per minute)

IV. Workflow

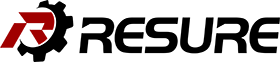

4.1 Flow Diagram

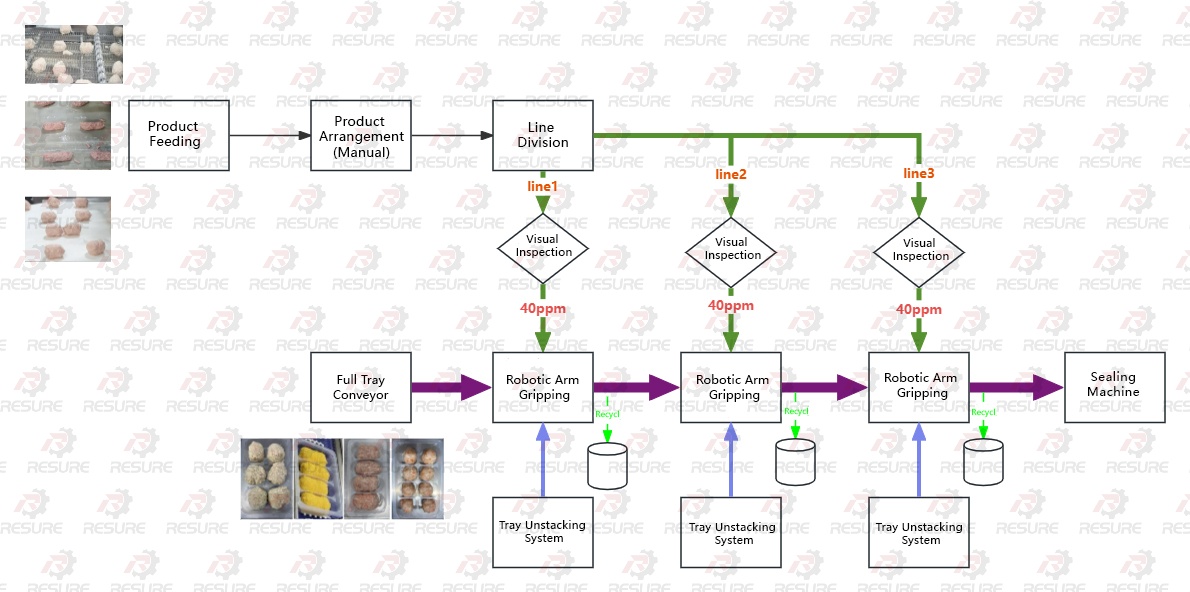

4.2 Overall Layout

4.3 Technical Specifications

○ The connection line transports products from four conveyor lines to three robotic arms for grabbing operations.

○ Each robotic arm uses a dual-grip mode, achieving an efficient working cycle of 40 ppm.

○ Equipped with a high-precision vision system, it processes incoming products from the dual conveyor lines in real-time, ensuring accurate tracking and grabbing.

○ Robotic arm combined with a positioning and rotation module, efficiently completes product gripping and placement tasks, ensuring smooth operations.

○ A dedicated recovery chute is designed for ungripped products, ensuring a clean and organized workflow.

○ The robotic arm features an integrated structure, simplifying assembly and debugging, and facilitating easier installation and maintenance.

4.4 Workflow

☆ Part 1. Connection Line

(1) Divergent Conveyor Mode: The connection line links the incoming material entry point, enabling four-way divergent conveyor operation to meet the multi-channel product handling requirements.

(2) Differential Conveyor Design: The conveyor line adopts a differential speed mode to precisely control the product spacing, providing stable and clear detection conditions for the downstream vision system.

(3) Material and Food Safety:

- The overall structure is made of food-grade 304 stainless steel, complying with food safety standards and offering corrosion resistance.

- The conveyor belt is made of food-grade POM material, ensuring the product transport process meets hygiene requirements.

(4) Drive System Configuration:

- Motor: Uses a high-performance SEW motor to ensure smooth and reliable conveyor line operation.

- Inverter: Uses the Inovance inverter.

☆ Part 2. Vision System

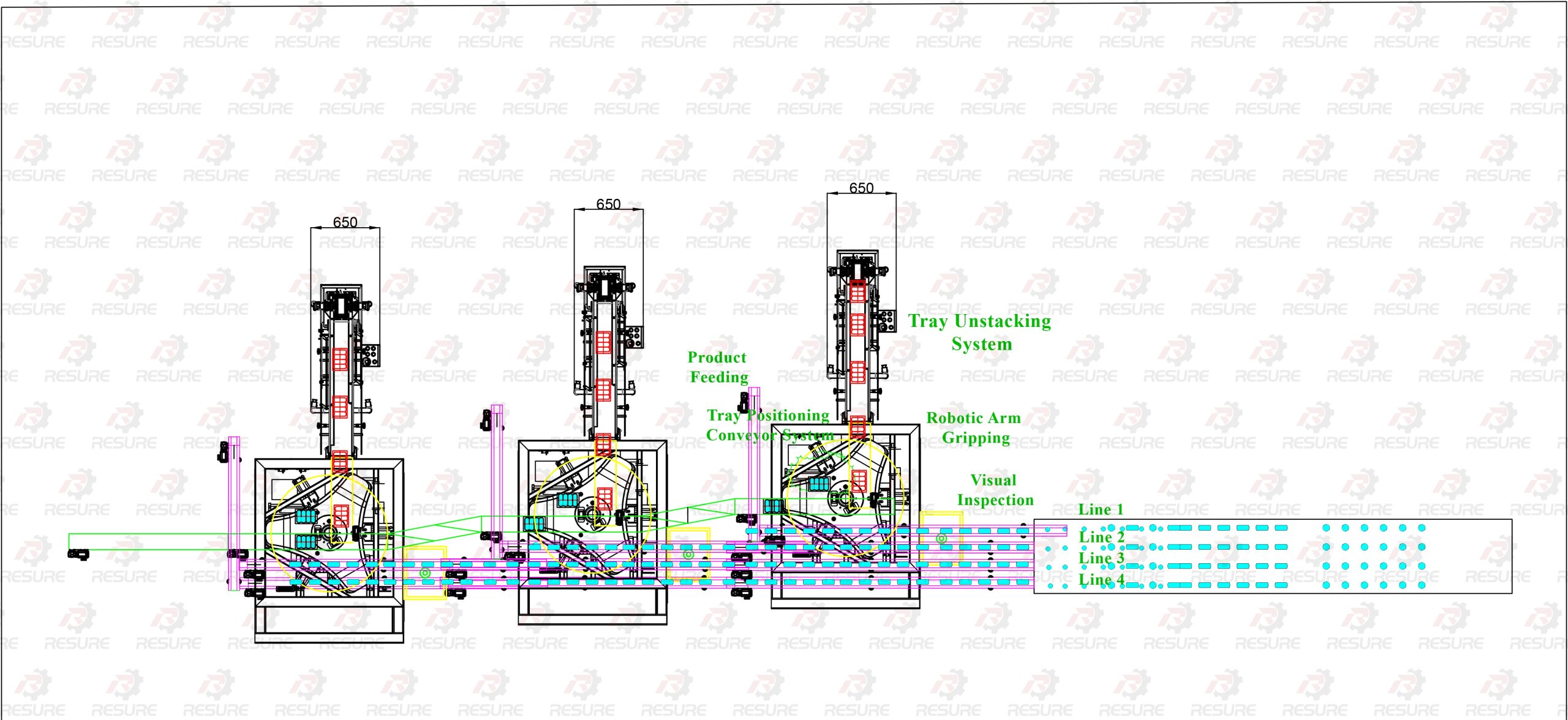

(1) Camera Configuration: The detection system utilizes a 5-megapixel global color camera, equipped with a 12mm lens, to provide high-resolution imaging. The camera is installed at a height of 410 mm, with fine adjustments available to meet various product detection needs.

(2) Detection Station Operation Mechanism: Products move horizontally along the conveyor line, entering the detection station one at a time. Upon reaching the sensing position, the camera is triggered to capture an image for real-time inspection. The inspection result (OK/NG) is automatically sent to the PLC system for subsequent processing.

(3) Real-time Display and Interaction: The custom software interface can display images and detection results in real-time, allowing operators to monitor and observe the process efficiently.

(4) Positioning and Communication: The camera communicates with the robotic arm’s tracking module to achieve real-time product position detection, ensuring precise grabbing and placement.

(5) Quick Changeover Function: The software interface supports model switching, allowing rapid changeover with preset templates and parameters. By clicking a button, the switch can be completed, greatly improving production efficiency and flexibility.

☆ Part 3. DLETA Robotic Arm Tray Palletizing

(1) Grabbing Logic: The robotic arm tracks the product position accurately and completes the grabbing based on the positioning data provided by the vision system.

(2) Robotic Arm Action Flow

● Robotic Arm Design: The system uses a soft claw, and the robotic arm’s control program operates in coordination to adapt to grabbing products of different shapes.

● Grabbing Process:

Step 1. The robotic arm enters standby mode after receiving the positioning information from the vision system.

Step 2. Once the product enters the grabbing range, the robotic arm calculates the trajectory and moves above the product.

Step 3. The robotic arm descends to the product’s position, the soft claws complete the grab, and after lifting, it moves above the tray. The soft claws open and place the product into the designated position on the tray.

(3) Tray Handling System:

The robotic arm framework integrates functions for tray positioning, full tray transfer, repositioning, and pushing mechanisms. And then full trays are conveyed by the conveyor line to the downstream process, ensuring continuous production.

(4) System Performance: The cycle speed satisfies 40 ppm, ensuring the efficient operation of grabbing and filling.

V. Highlights

- Fully Automated Control: The entire production line operates fully automatically, with the PLC system as the central control unit coordinating efficient collaboration across conveying, inspection, gripping, tray loading, and sealing processes.

- Intelligent Vision Inspection: Equipped with a high-precision vision system, the line automatically identifies product shape, position, and quality, reducing manual intervention and enhancing packaging consistency.

- Soft Gripper Technology: Ensures flexible and precise product handling, avoiding damage or deformation caused by traditional rigid grippers.

VI. Configuration

1. Product Conveying System: The conveyor system evenly transports incoming products to the robotic working area. It supports adjustable speeds to ensure a stable product flow, facilitating subsequent operations.

2 . Vision Inspection System: This system performs real-time scanning and detection of products on the conveyor belt, identifying their shape, size, and position while removing defective items. It ensures precision during the gripping phase.

3. Robotic Arm with Soft Gripper Device: The robotic arm, equipped with soft grippers, uses location data provided by the vision system to gently and accurately pick up products and place them into designated trays. The soft gripper design ensures safe handling of fragile and easily deformable items.

4. Tray Conveying System: This system accurately transports empty trays to the robotic tray-loading position. It synchronizes with the robotic gripper to enable fast and efficient loading of trays.

5. Tray Sealing Machine: The sealing machine ensures airtight packaging for the tray-loaded products, preserving freshness and ensuring packaging integrity. Both soft film and rigid film sealing options are available to meet customer requirements.

6. Control System(PLC + HMI) :The PLC system coordinates the interaction of all equipment on the production line, while the HMI provides an intuitive user interface for real-time monitoring and parameter adjustments, ensuring smooth and efficient operations.