Fried Rusk

Fried Rusk Automatic Tray Packaging Solution

I. Overview

1. 1 Background

This project aims to provide the customer with a fully automated packaging solution for fried rusks. The customer requires that the rusks be packed into trays, followed by sealing and labeling processes, to improve production efficiency and ensure product quality. The primary product involved in this project is fried rusks, with the following characteristics:

○ Product Characteristics:

Form: The rusks are mainly in slice or stick form, with a moderate size and light weight.

Weight: Each tray contains 100g ± 3g of rusks. Individual pieces weigh between 2g and 5g, with an average weight of 3g.

Fragility: Rusks are fragile and require precise handling during loading and distribution to avoid breakage.

Stability: Proper sealing is crucial for maintaining product quality over time during storage and transportation.

Stick

Slice

○ Target Output:

The customer expects the system to support a production capacity of 1,800 -2,400 trays per hour, meeting the demands of large-scale manufacturing.

○ Quality Requirements:

- Accurate Weighing: Each tray must meet the specified weight tolerance of ±3g.

- Sealing Quality: High sealing integrity is required to prevent moisture ingress and flavor deterioration.

- Automation Level: The system should minimize manual intervention, improving overall automation and process stability.

- Printing Accuracy: Date, production batch number, barcode, and QR code must be printed clearly and accurately on each tray for traceability.

1.2 Solution Objectives

To meet the customer’s requirements, a high-efficiency, fully automated packaging system for fried rusks is designed, ensuring the entire process adheres to the following key goals:

○ Automated Production:

Achieve full automation from product loading to tray sealing and output, minimizing manual involvement and significantly improving production efficiency.

○ Precise Control:

Utilize a high-precision weighing system and a gentle product feeding mechanism to ensure accurate tray weights, reduce product breakage, and prevent quality issues.

○ Flexible Sealing Options:

Offer multiple sealing modes—including vacuum, MAP (Modified Atmosphere Packaging), gas flushing, or standard sealing—to maintain product freshness and meet different customer needs.

○ High-Quality Packaging:

Ensure excellent sealing performance, clear and accurate labeling, and a clean, professional packaging appearance through the use of advanced sealing and printing equipment.

II. Technical Specifications

○ Capacity: 1,800–2,400 trays per hour

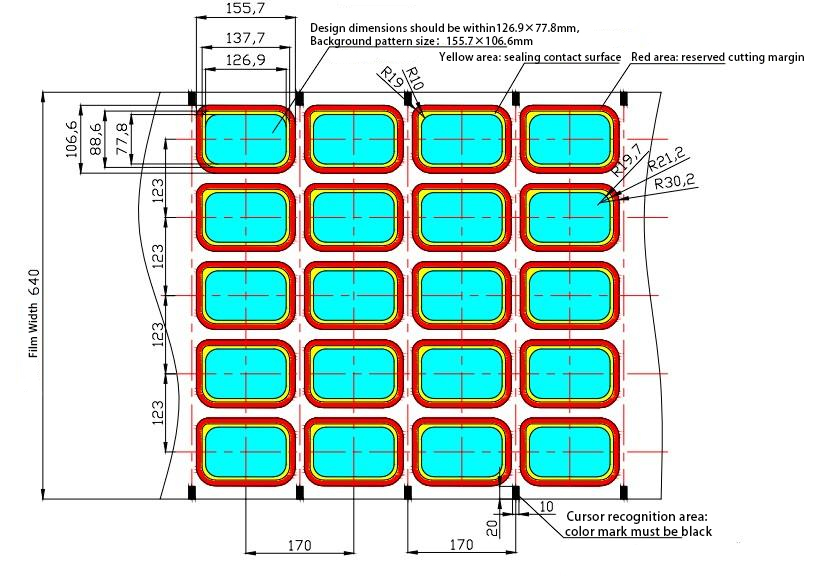

○ Tray Size: 142 x 92 mm

○ Product Weight: 100g ±3g per tray; individual product weight ranges from 2g to 5g, with an average of 3g per piece or stick

III.Process Flow

○ Automatic Feeding and Weighing:

Bread crisps are conveyed to the multihead weigher platform via the inclined conveyor. The automatic weighing system ensures precise portioning and discharges the product into trays. The system ensures even distribution to prevent stacking or breakage.

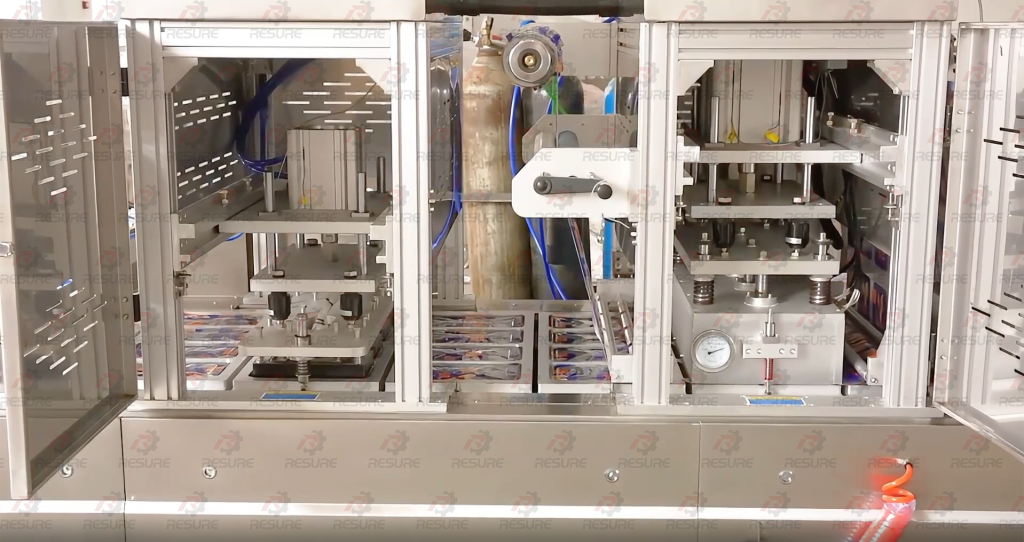

○ Tray Conveying and Positioning:

Trays move along the conveyor system in set cycles and are precisely positioned at the sealing station. Before sealing, the system automatically cleans the tray edges to remove debris or residue that may affect seal quality, ensuring better sealing performance.

○ Sealing:

Depending on the product’s preservation requirements and customer preferences, vacuum MAP sealing, gas flushing, or standard sealing methods can be applied to ensure freshness and airtightness.

○ Printing and Marking:

After sealing, the system prints the production date, batch number, barcode, and QR code on each package, ensuring all product information is complete, legible, and traceable.

○ Final Output:

Finished trays pass through a checkweigher. Any product not meeting the weight standard is automatically rejected. Qualified products are conveyed to the next packaging stage or directly to storage. An optional smart sorting system can be integrated for automatic classification.

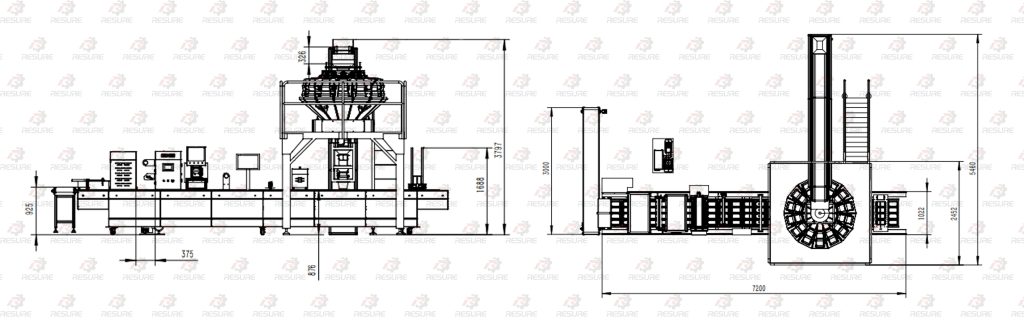

IV. Layout Design

Principles

✅ Compact and Efficient: Machine is arranged to minimize material transfer distances, optimizing production flow and enhancing overall efficiency.

✅ Smooth Integration: The layout ensures smooth transitions between equipment, minimizing production bottlenecks and maximizing automation performance.

✅ Easy Operation and Maintenance: Reserve sufficient space for operation and maintenance to facilitate personnel access and workflow.

V. Configuration

Automatic Tray Denester

The automatic tray denester is designed to individually separate and release stacked trays onto the designated position on the production line. Operators preload trays into the denester magazine, which has a capacity of up to 600 trays, allowing for approximately 15 minutes of autonomous operation without manual intervention.

Large Incline Conveyor

Used to lift and transport the bread crisps to the multihead weigher platform, featuring AISI 304 stainless steel buckets with a capacity of up to 50 kg. Designed for 15 minutes of autonomous operation, with an optional additional conveyor belt to extend the run time. The belt system is servo-driven and made of food-grade materials.

Multihead Weighing and Discharging System

Equipped with 14 weighing hoppers, each with a 2.5L capacity, combined with a cascading product distribution system to ensure accurate product allocation and precise discharge into trays. The system is fitted with an independent multifunctional display for easy operation and real-time monitoring.

Vibration Unit

Reduces product accumulation through vibration, ensuring even distribution of materials within the trays.

Flattening Unit

Ensures the product surface is leveled, evenly spreading the material across the tray and preventing excessive piling.

Tray Edge Cleaning Device

Cleans the tray edges before sealing to remove any product crumbs or debris, ensuring clean edges and improving the sealing quality.

Multi-Column Printer

Capable of printing production dates, batch numbers, and other information to ensure easy traceability.

Multi-Function Dual-Sealing Packaging System

This system offers flexible sealing options, including vacuum Modified Atmosphere Packaging (MAP) sealing, gas flushing sealing, and standard sealing, to accommodate different product preservation needs and ensure optimal shelf life.

Tray Ejection Device

After sealing is completed, the finished trays are ejected upward and fed onto the conveyor belt, proceeding to the next stage of packaging or storage.

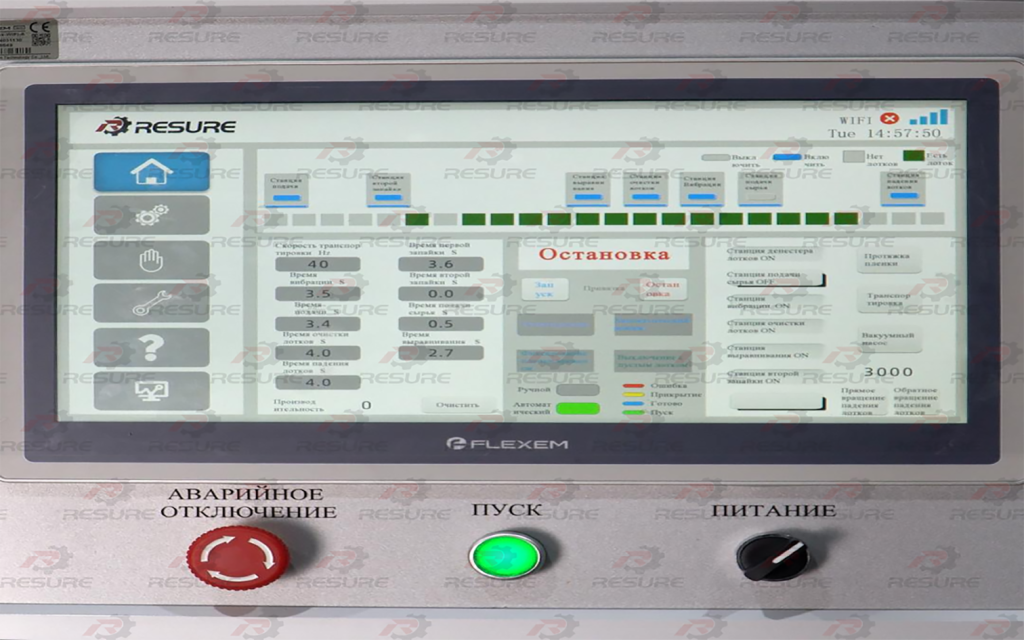

Multilingual Control System

The entire production line is controlled by an intelligent PLC system, with the operation interface customizable in the customer’s preferred language.

Inspection System

Automatic weight inspection ensures that the packaged products meet the required weight and quality standards. Non-conforming products are automatically rejected.